Authors: Alex Selimov, Kevin Chu, and David L. McDowell

Link to publisher

Click here to download manuscript preprint

Abstract:

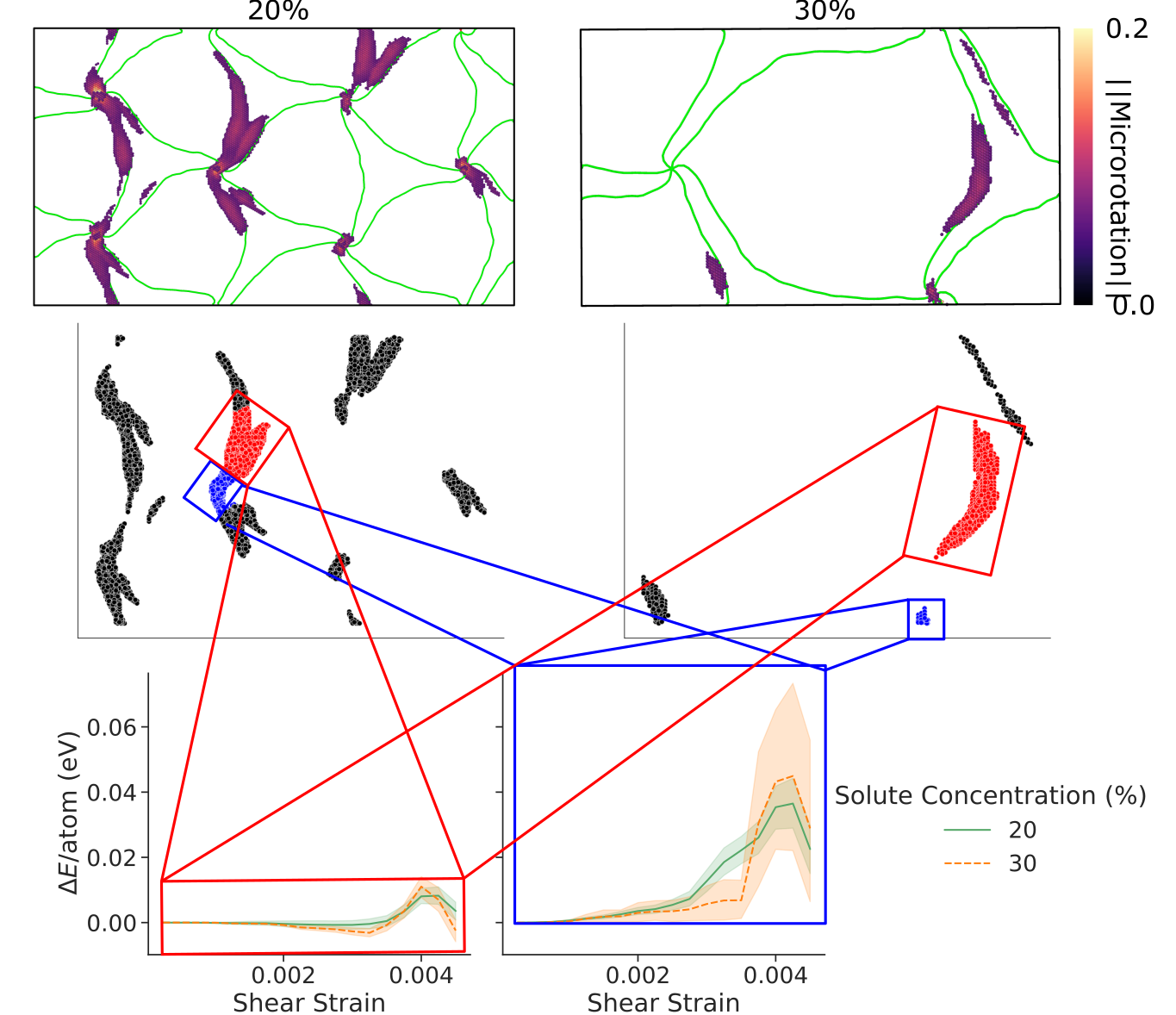

Intermixing of chemical species as a result of interdiffusion during the manufacturing of metallic nanolaminates leads to diffuse interface structures which have distinct properties compared to corresponding atomically sharp interfaces. The effect of interdiffusion-induced changes to the interface structure on interface shear strength is complex due to the presence of solute atoms and a reduced misfit dislocation density. The shear responses of {111} Cu/Ni nanolaminate interfaces with varying levels of interdiffusion are studied using atomistic methods to elucidate the effect of interface structure changes on shear deformation mechanisms. Models with diffuse interfaces exhibit improved interface shear strength relative to the atomically sharp case; however, shear strength does not increase monotonically with solute concentration. The distribution of maximum changes in energy per misfit node and non-uniform misfit node displacements, filtered using microrotation vector analysis, suggest heterogeneous interface resistance to sliding. No strong correlation is found between solute concentration near misfit node centroids and misfit node displacements, indicating the importance of the longer-range misfit dislocation structure. Increased activation of misfit dislocation glide is associated with larger solute concentrations as a result of increased misfit node displacements. Analysis of change in energy during the shear deformation process, however, reveals that interface sliding is dominated by the misfit node behavior. These findings highlight the importance of modeling realistic diffuse interface structures and emphasize the competing effects of solute concentration and interface misfit dislocation density.